IR For Welding Of Plastics

There are many types of welding in the plastics industry but at Victory we feel that using Infrared has great advantages, especially for the welding of plastic pipes.

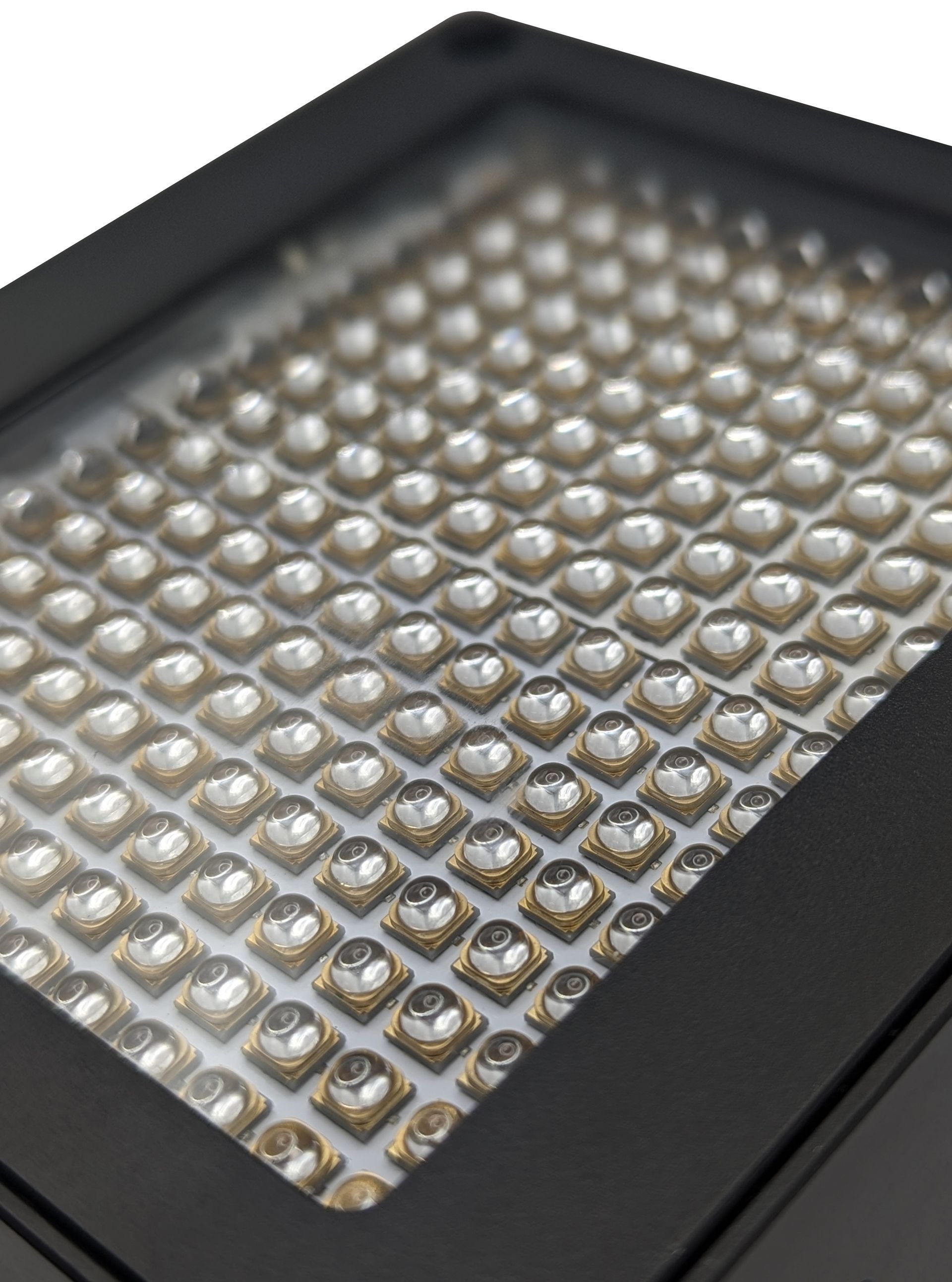

IR welding is a non-contact heating technique to melt and then fuse thermoplastic parts together using the energy from Infrared radiation. IR welding typically uses a range of wavelengths from 800 – 1100nm to heat, melt and fuse the interface between two plastic parts through the absorption and conversion of the IR energy into heat

IR welding is a much faster and is more controllable than alternative options of plastic welding. Various IR emitters can be used and developed for your exact requirement. It can represent a cost saving and more productivity due to the fast nature of the process which is desirable for all in the industry

Contact our Sales Team for further information and guidance on how infrared can help your business.

sales@victorylighting.co.uk or call +44 (0) 1525 487960

#infrared #plastics #welding